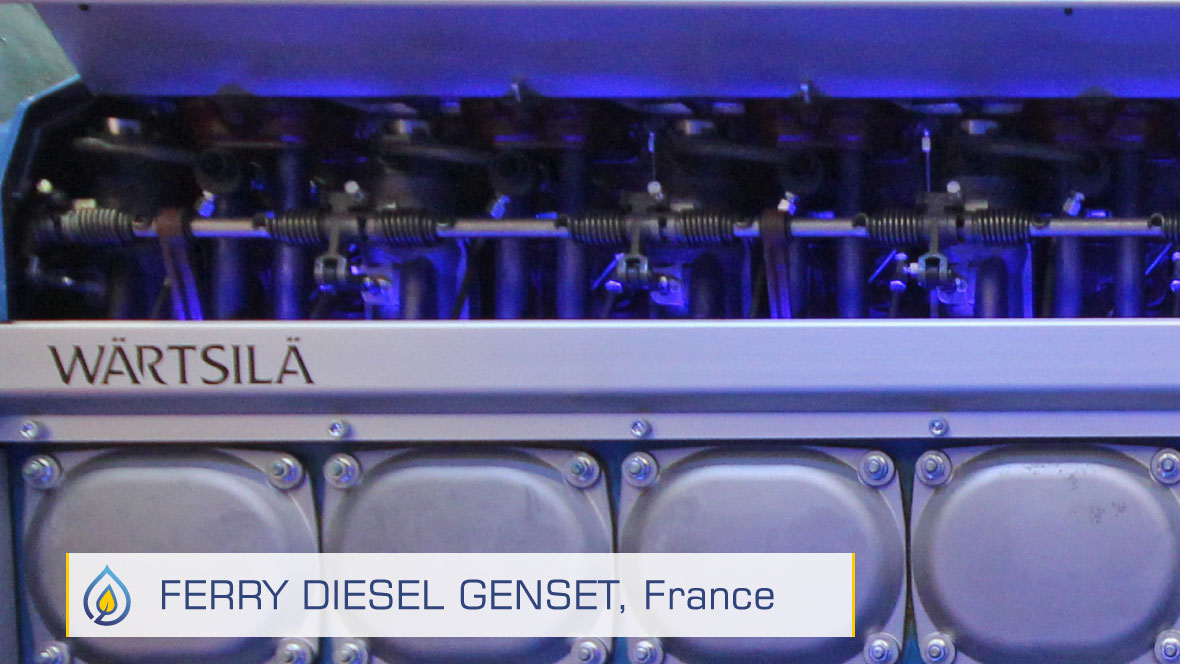

The shipping company Naviera de Galicia S.A. operates three cargo vessels: the M/V Mandeo and the sisterships M/V Finita R and M/V Manuela E, all powered on intermediate fuel oil 180.

After having used a classic chemical additive during four years, the company decided to evaluate the XBEE Enzyme Fuel Technology on board the cargo ship M/V Finita R. The vessel is equipped with a Wärtsilä W6L32 main engine of 2,760 kW.